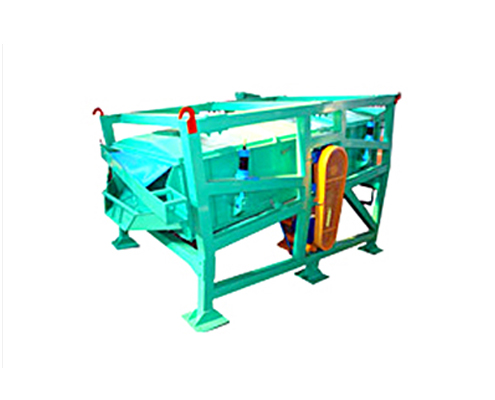

Screen Air Separator

This Pre-cleaner is mainly designed to cater to pre-cleaning of agro seeds at modern processing plants. It can be placed before storage silo or even in plant operations.

Salient Features:

- The Screen air Separator is of positive eccentric, four bearing design type.

- High speed, vibrating screen which ensures accurate, high quality separation at high capacity.

- The adjustable feed hopper regulates feed as desired and uniform distribution of material across width of screen.

- The outboard bearing isolation mount combined with advanced balancing systems make the frame vibration less, allowing the machine to be operated on any structure.

- The outboard bearing isolation mount combined with advanced balancing systems make the frame vibration less, allowing the machine to be operated on any structure.

- Quick access clamps permit easy access for interior cleaning and faster screen changing.

- Optional stainless steel construction permits the machine to be used for food, chemical and other specialized application like de-watering.

- Ball compartments incorporated into the screen support grid allow an optional ball cleaning system.

- Several models are available for capacity up to 100 TPH and above on wheat basis.

- Optional — Variable Speed drive facilitates to adjust optimum speed for best cleaning results

The Screen Separator may be equipped with various options.

PRE SCALP UNIT is equipped with a short screen, somewhat coarser than the “top” scalp screen in the machine. This makes for scalping of the large over-size objects before the product enters the Screen.

PRE-ASPIRATOR is used to remove hulls or dust and other light contaminants before the product enters the Screener, thus making the product more flow able at the start of the screening operation.

POST ASPIRATOR is used when the finished product is to be the “plus” of the screen. This product is then discharged through the aspirator which removes dust or other light contaminants.

FOUR DECK SCREEN SEPARATOR can be supplied for as high capacity as 100 TPH, with split-flow arrangement.

SCALPER DRUM & SUTLI SEPARATOR can be provided at Feed inlet to remove bag Sutli jutes before feeding the material into Pre-Aspirator